Ozone Accessories

There are three primary technologies used to monitor and measure ozone:

Electrochemical cells, HMOS / GSS, and UV.

Electrochemical ozone sensor uses a porous membrane that allows ozone gas to diffuse into a cell containing electrolyte and electrodes. When ozone comes into contact with the electrolyte, a change in electrochemical potential occurs between the electrodes causing electrons to flow.

In zero air, little or no electron flow occurs. As the presence of ozone increases, the electrical signal increases proportionally. The monitor interprets this signal and displays the ozone concentration in PPM (parts per million).

| Advantages | Disadvantages |

|---|---|

| Linear Response | Humidity can affect Sensor Readings |

| Good Repeatability and Accuracy | Sensitive to EMF/RFI |

| Very quick response time - 1-2 Seconds | Limited sensor life storage |

| Can measure ozone accurately up to 20 ppm and Moderate resistance to Interference | Decreased accuracy at low ozone levels |

Semiconductor-Based Ozone Sensors: Heated Metal Oxide Sensor (HMOS) Gas Sensitive Semiconductor (GSS)

A heated metal oxide semiconductor (HMOS) sensor works by heating a small substrate to high temperature (around 300-deg F / 149-deg C). At this temperature, the substrate is very sensitive to ozone and exhibits a change in resistance and displays the corresponding ozone level on the display as either PPM or PPB..

| Advantages | Disadvantages |

|---|---|

| Very responsive to low levels of ozone ozone (below 0.1 ppm) | Slow start-up (can require 8-24 hours warm-up time) |

| Least expensive monitoring technology | Slower response time to ozone (compared to electrochemical) |

| Excellent repeatability and accuracy | Very sensitive to interference |

| Long Sensor Life if stored properly | Shorter battery life due to heated sensor element |

| Not linear at ozone levels above 1 ppm | |

| Max. Temperature threshold of 122 F or less (depending on model) |

UV-based Ozone Analyzers

UV-based ozone analyzers function on the principle that ozone particles will absorb UV light with a wavelength of 254 nm. When this wavelength of UV light is created and passed through an air chamber, the amount of UV light absorbed is proportional to the amount of ozone present in that airspace. The amount of UV light absorbed in the chamber is interpreted as ozone concentration and displayed or output for our use.

The primary advantage Of This technology are its accuracy and stability over a wide range of ozone concentrations and Since the principle used is very wave length-specific, few other gases interfere. This results in much more accurate readings, even in outdoor environments to provide reliable,stable readings

| Advantages | Disadvantages |

|---|---|

| Very accurate (within 1%) | Higher cost than electrochemical or HMOS / GSS |

| Very linear at any ozone levels | |

| Low ppb detection limits with accuracy | |

| Minimal cross sensitivity to other gasses or interferences | |

| Can read high concentrations (20% or higher) | |

| Durable design with excellent longevity |

| System Sensors | Application |

|---|---|

| Electrochemical Cells | - Personnel (portable) safety monitoring (especially for shift-long use) - Ozone leak detection - Stationary ambient ozone monitoring - Ozone control scenarios (alarms, exhaust fans, ozone generators, etc) |

| HMOS / GSS | - Ambient ozone safety monitoring (especially below 0.1 ppm) - Portable ozone monitoring (especially below 0.1 ppm) - Ozone control scenarios (especially below 0.1ppm) - Ozone leak detection |

| UV Based Ozone Gas Sensor | - Low Concentration - Cold storage facilities - Microarray applications - Semiconductor fabrication facilities - Ozone compatibility testing - Medium Concentration - Off-Gas Monitoring - High Concentration - Industrial ozone generator control - Ozone research - Ozone compatibility testing |

Ozone Compatible Material

| Material | Ratings |

|---|---|

| Alluminium | B - GOOD |

| EPDM | B - GOOD |

| Glass | A - EXCELLENT |

| Teflon | A - EXCELLENT |

| Viton | A - EXCELLENT |

| Natural rubber | D - Severe Effect |

| Nylon | D - Severe Effect |

| Stainless Steel 304/316 | A - EXCELLENT |

| Titanium | A - EXCELLENT |

| CPVC | A - EXCELLENT |

Automation System

| Ozone Automation Application | Boaster PUMP | PLC | Sensors |

|---|---|---|---|

| Mineral Water | Stainless Steel 304/316 | Yes | ORP/Dissolve Ozone Sensor |

| Process Water | Stainless Steel 304/316 | Yes | ORP/Dissolve Ozone Sensor |

| Swimming Pools | CI/SS | Yes | ORP Meter |

| STP/ETP | Stainless Steel 304/316 | Yes | ORP/Dissolve Ozone Sensor |

| Cooling Tower | Stainless Steel 304 | Yes | ORP/Dissolve Ozone Sensor |

| Air Treatment | N.A | Yes | Ozone Air Detector |

| Food Washing | Stainless Steel 316 | Yes | Dissolve Ozone Sensor/Ozone Air Detector |

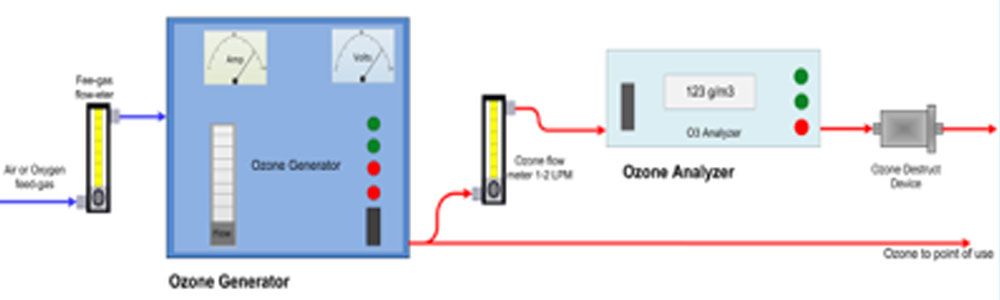

Ozone Lab Unit

| Application | Features |

|---|---|

| STP/ETP | 230 volts Input 50 Hz |

| Process Washing | Oxygen Gas In feed Cylinder |

| Laundry / Bleaching | Ozone Ouput Validated |

| Paper & Pulp Bleaching | Easy to Install |

| Oxidation Process | Compact Unit |

| Advance Oxidation Study | Portable |

| Air Treatment / Process | Stainless Steel Model Available |