Oxygen Generator PSA

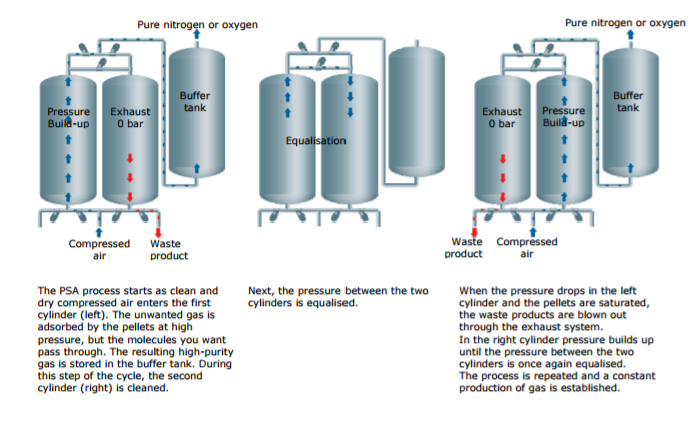

This process consists of 2 vessels filled with Molecular Sieves and Activated Alumina. Clean compressed air at 30° C temperature is passed through one vessel and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back into atmosphere. Upon saturation of the molecular sieve bed, the process switches Oxygen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Oxygen production and regeneration ensuring Oxygen gas is continuously available to your process.This Type of System is Mostly Centralized Oxygen Input gas For Larger Ozone Application

MAIN PARTS:

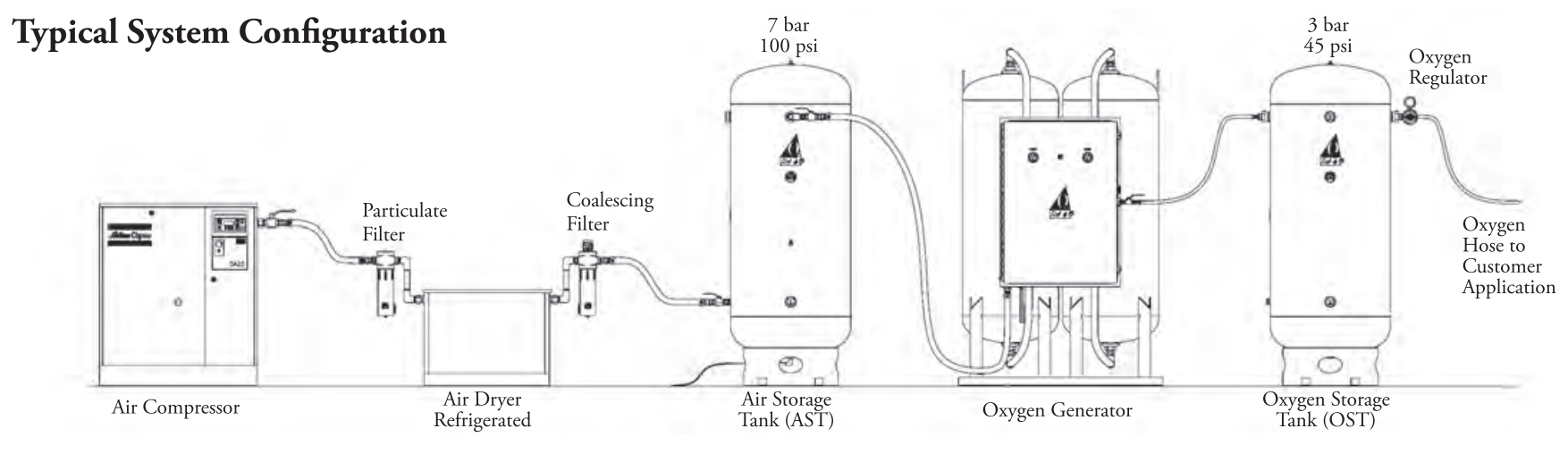

- Oil Free Compressor

- Filters

- Dryers

- Valves

- Molecular Sieve Beds

| Model | Indigenious Manufactured |

|---|---|

| Compressor Type | Reciprocrating type / Piston Type Compressor |

| Power Supply Input | 3 Phase |

| MOC | Mild Steel |

| Technology | PSA |

| Flow | 0-500 Lpm |

| Oxygen Purity | 95% |

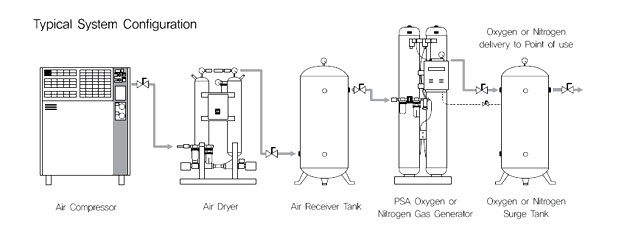

| Process | Compressor – Tank -> Dryer - PSA - Oxygen Tank |

| Main Parts | ZMS / Solonied Valve / Timer |

| Instruments | Oxygen Meter Indicators Optional |